How Belt Conveyor Systems Work

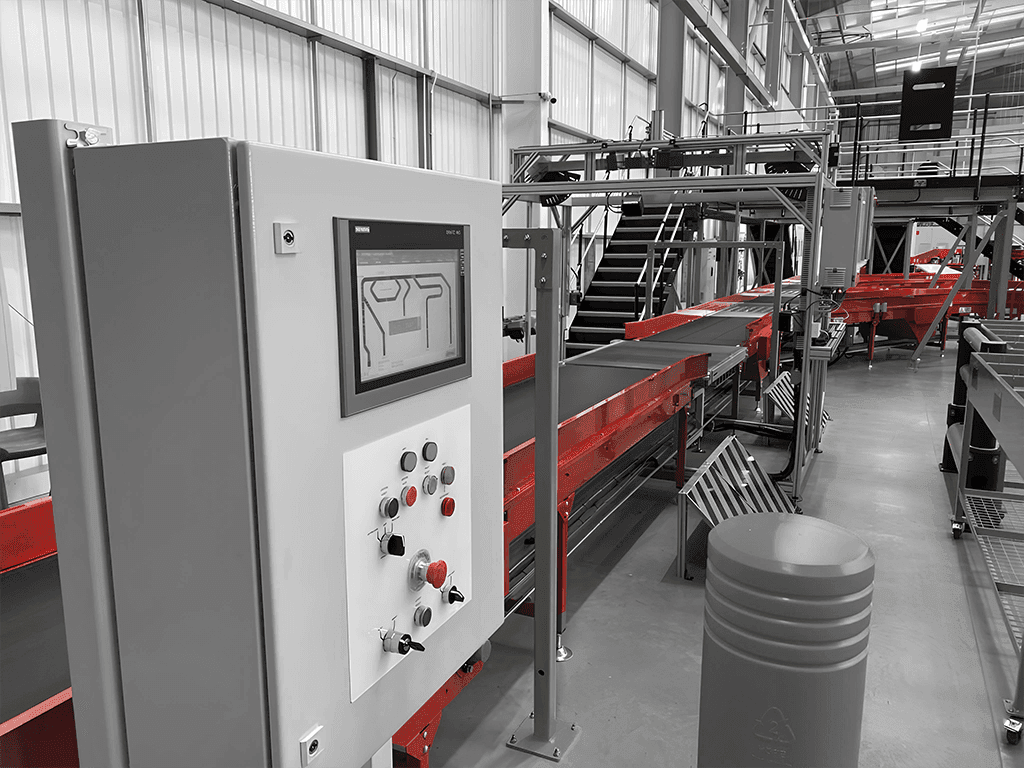

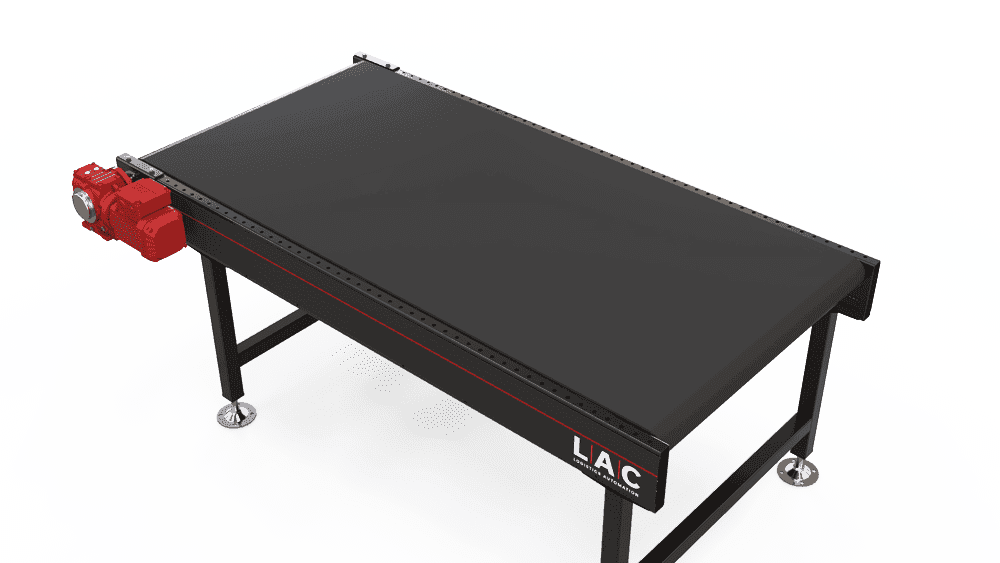

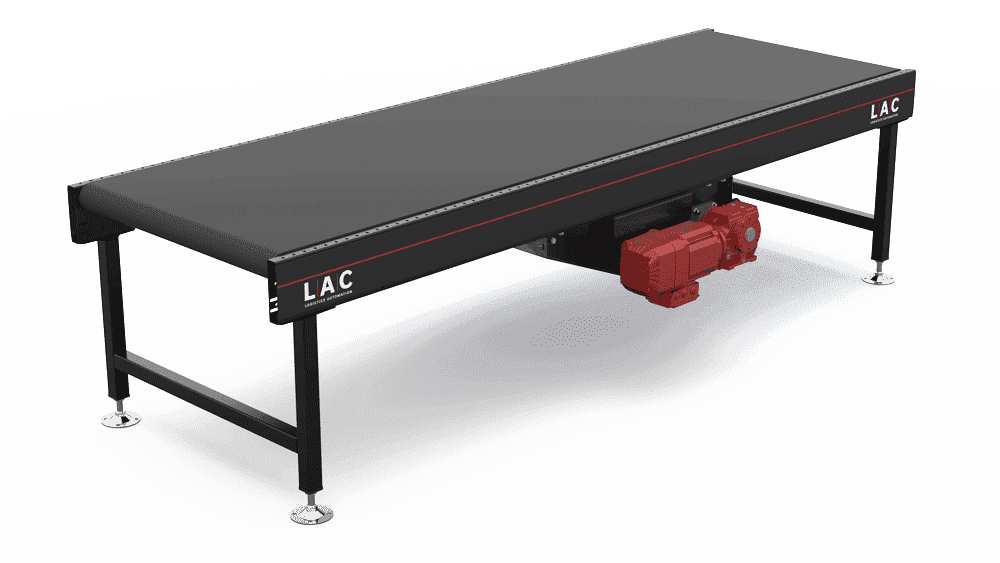

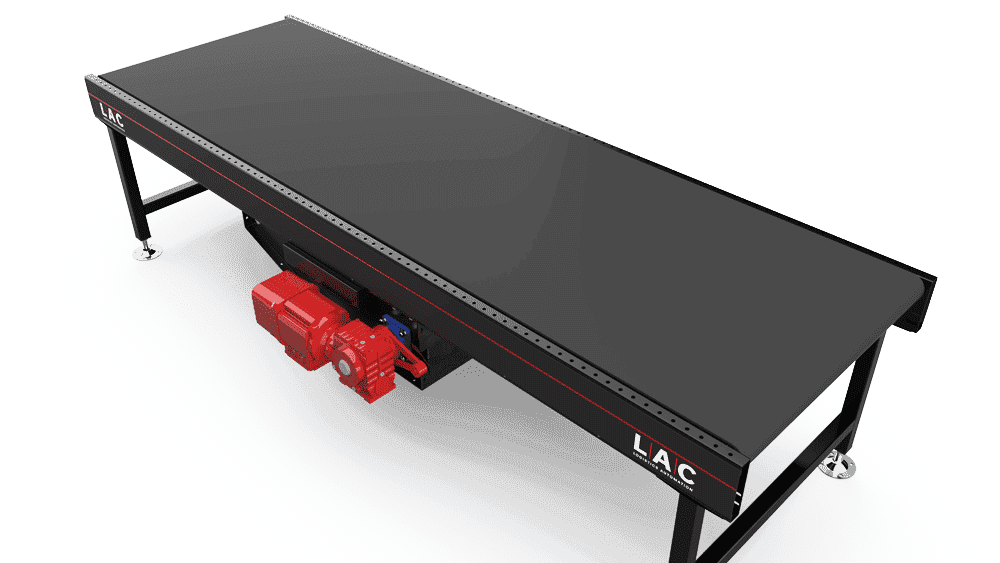

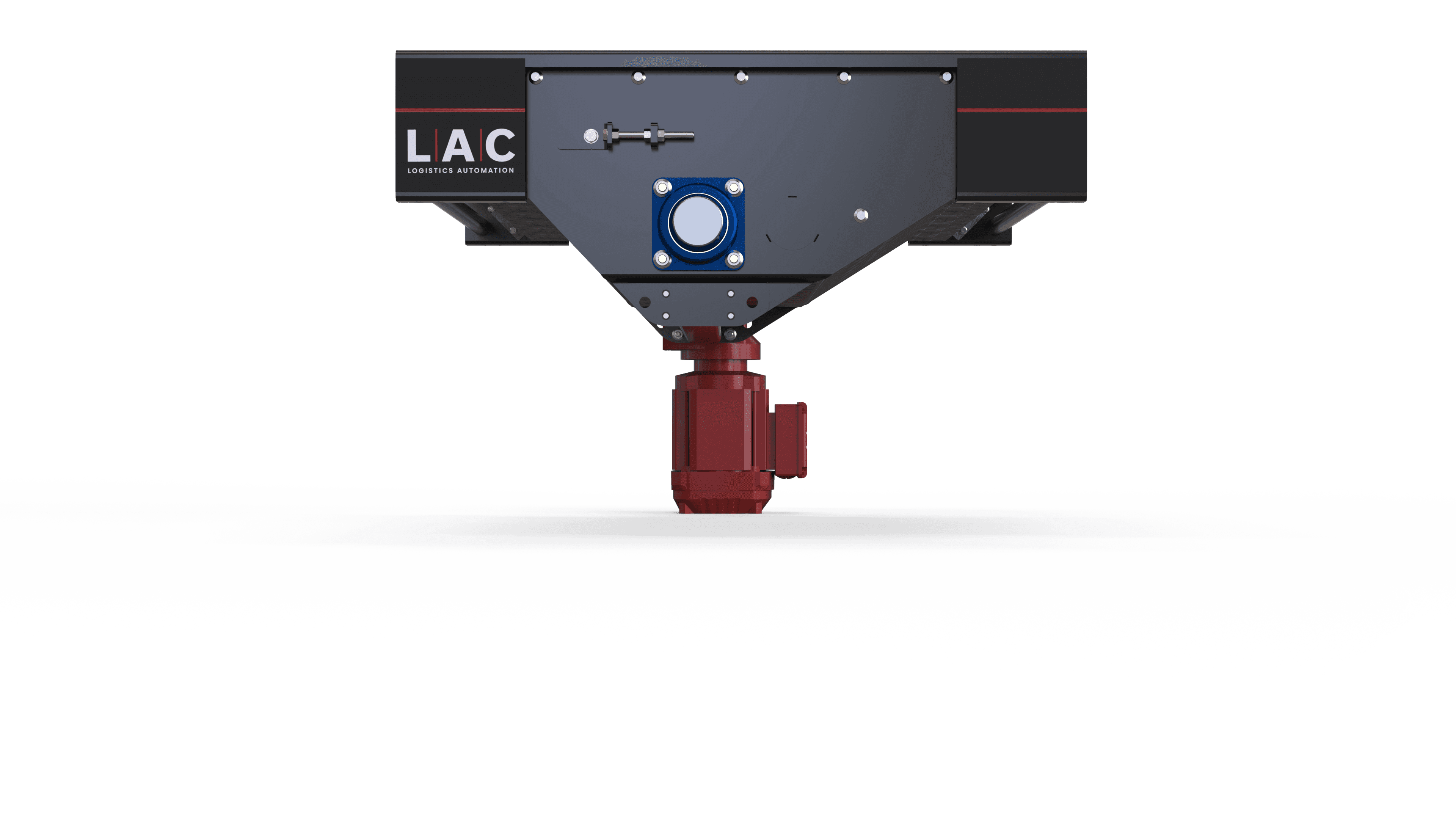

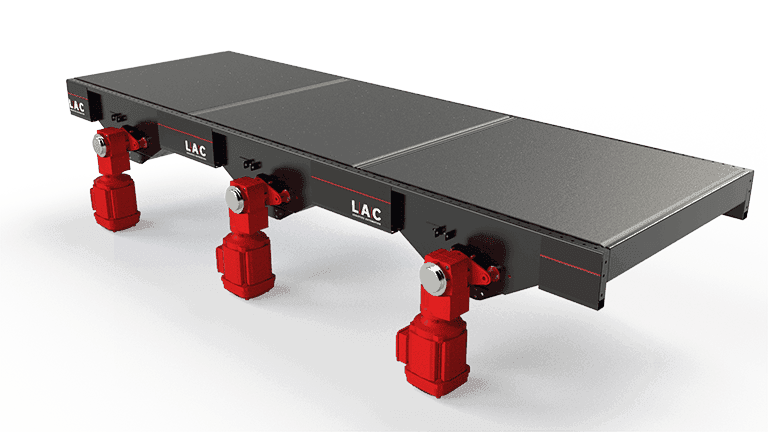

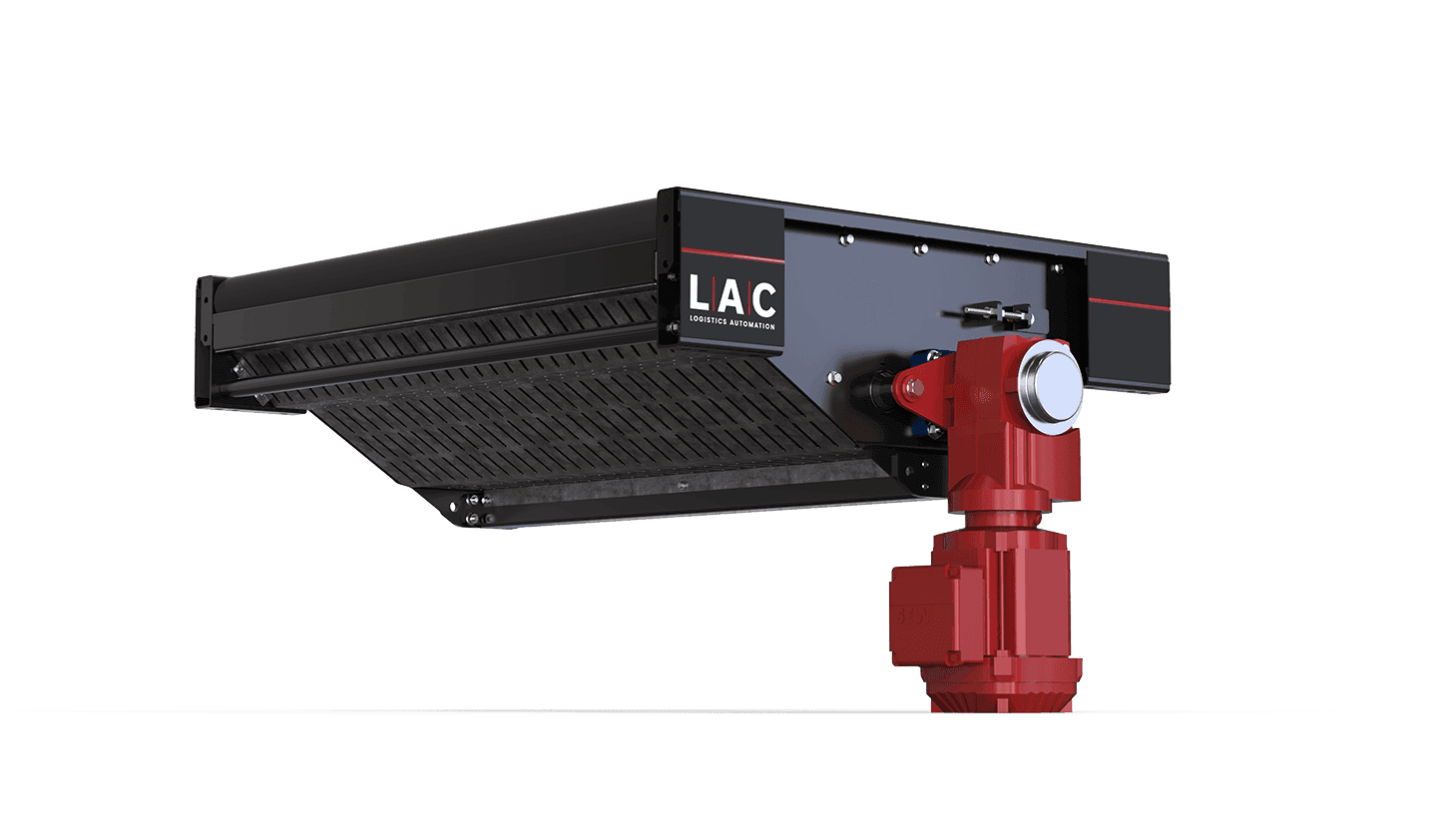

Belt conveyor systems operate by transferring power from the drive unit to the drive roller, pulling the belt around the system at a controlled maximum belt speed. Return rollers, tensioning systems, and idler pulleys ensure stable belt tracking and efficient operation.

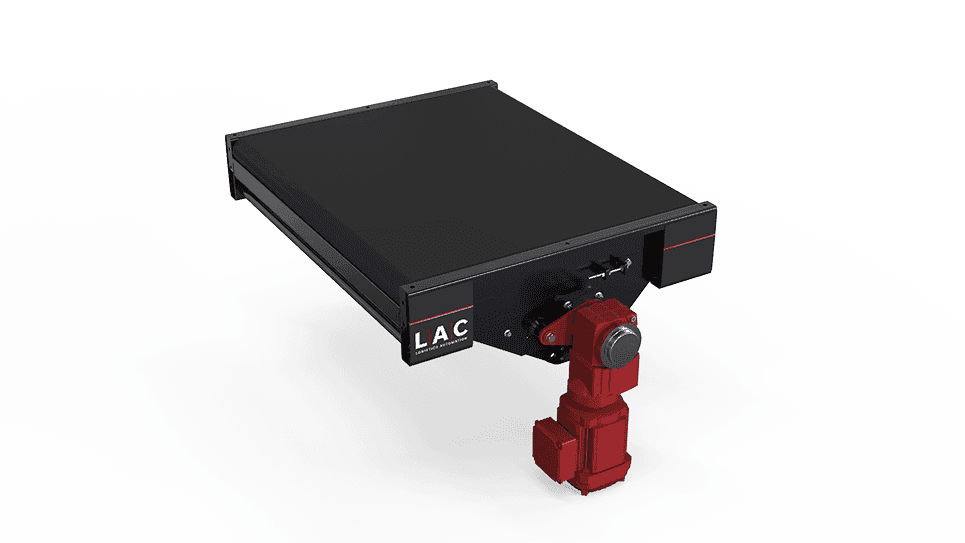

A properly engineered belt guide arrangement, including adjustable side guides, helps maintain belt alignment and protects product flow. Optional features such as pop out rollers simplify maintenance, while precision-engineered roller bedding ensures smooth operation across varying loads.

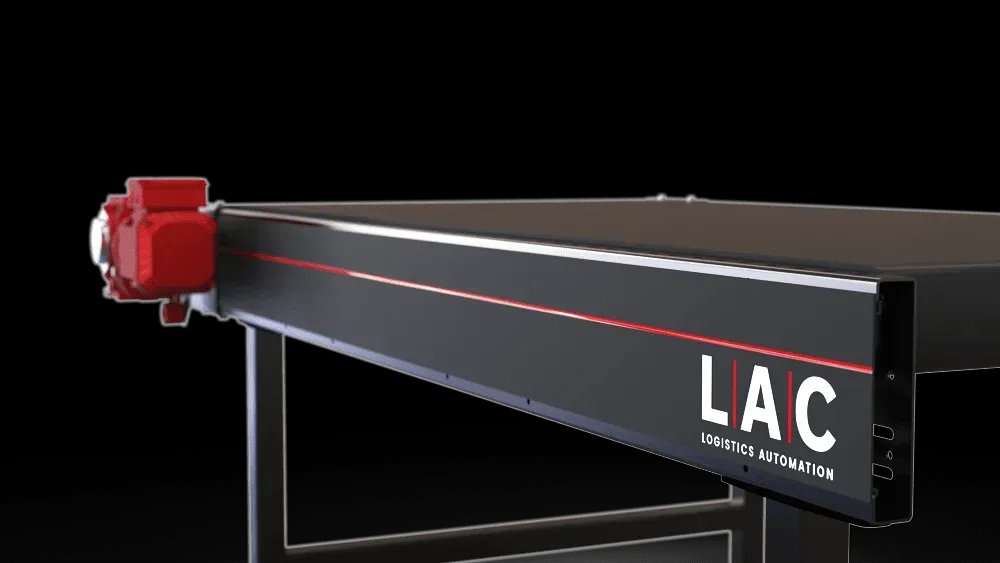

Systems can be configured as end-driven belt conveyors or alternative drive layouts depending on space, load, and operational requirements.