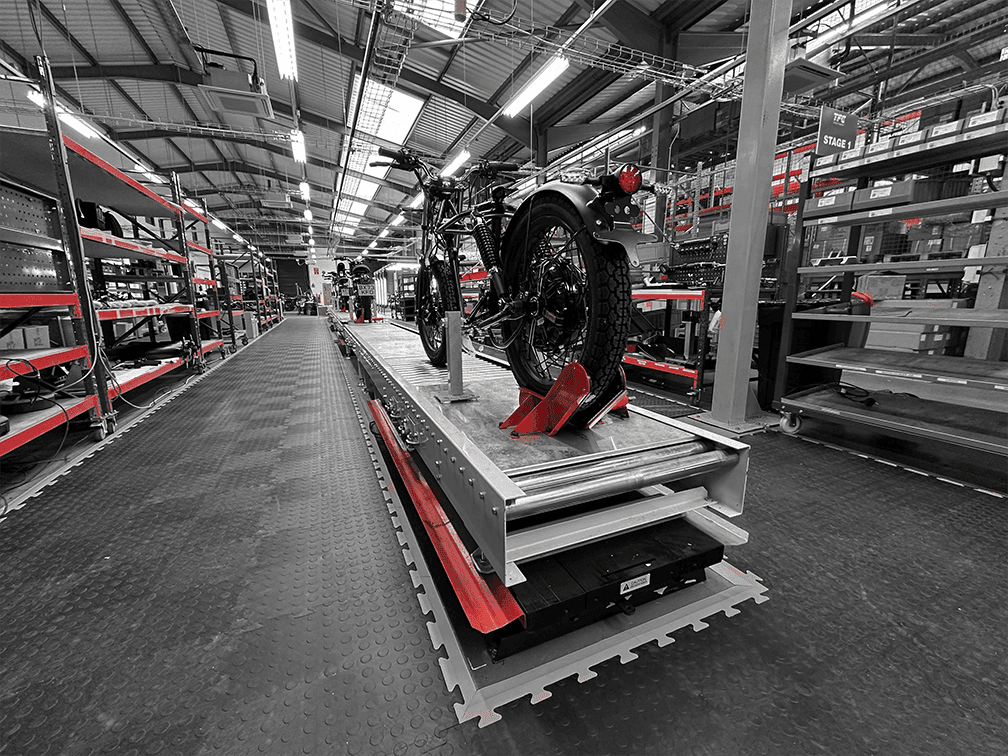

Conveyors serve as the arteries connecting different zones within an automated facility. These systems transport goods between receiving docks, storage areas, picking stations, packing zones, and shipping lanes without manual carrying or forklift traffic.

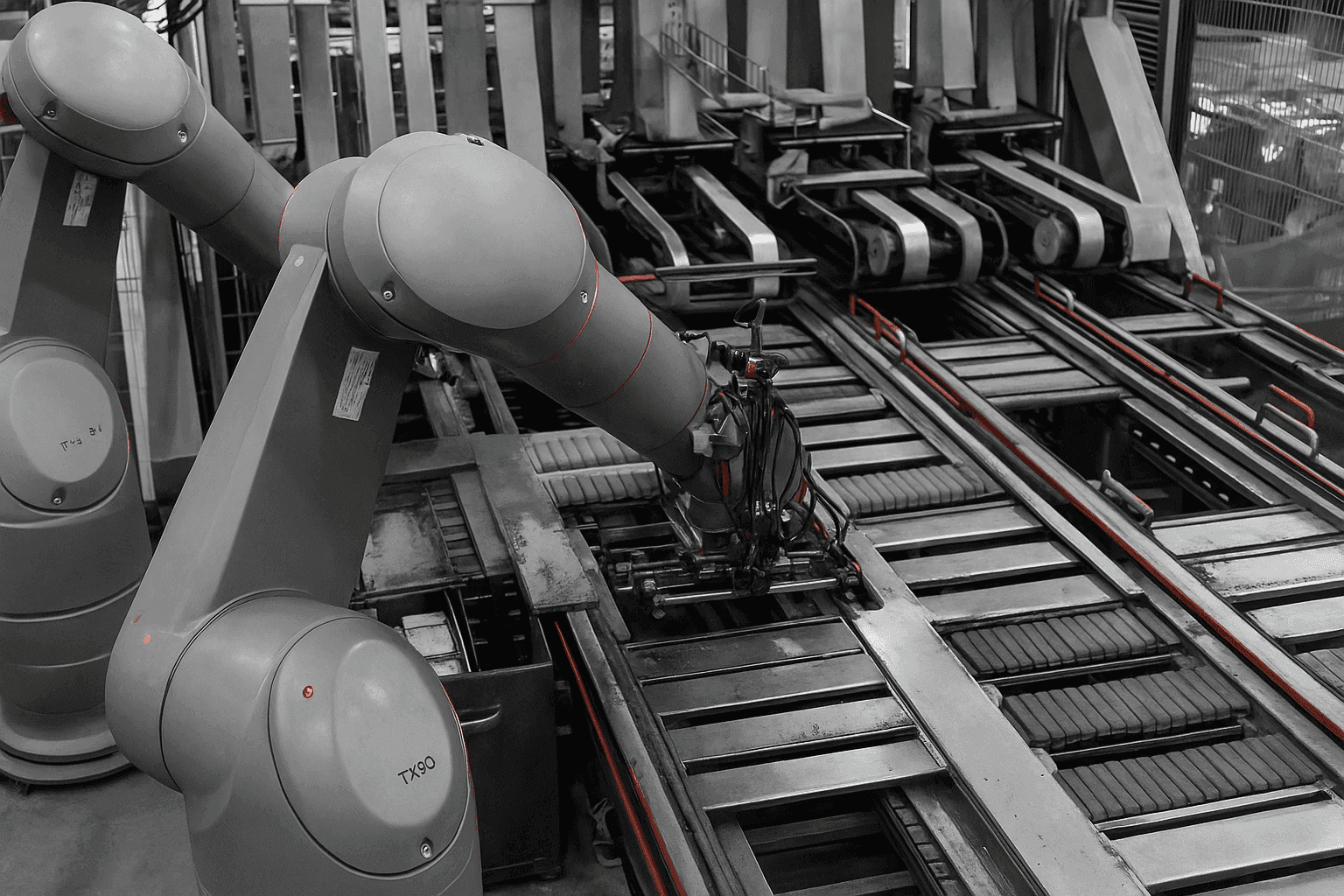

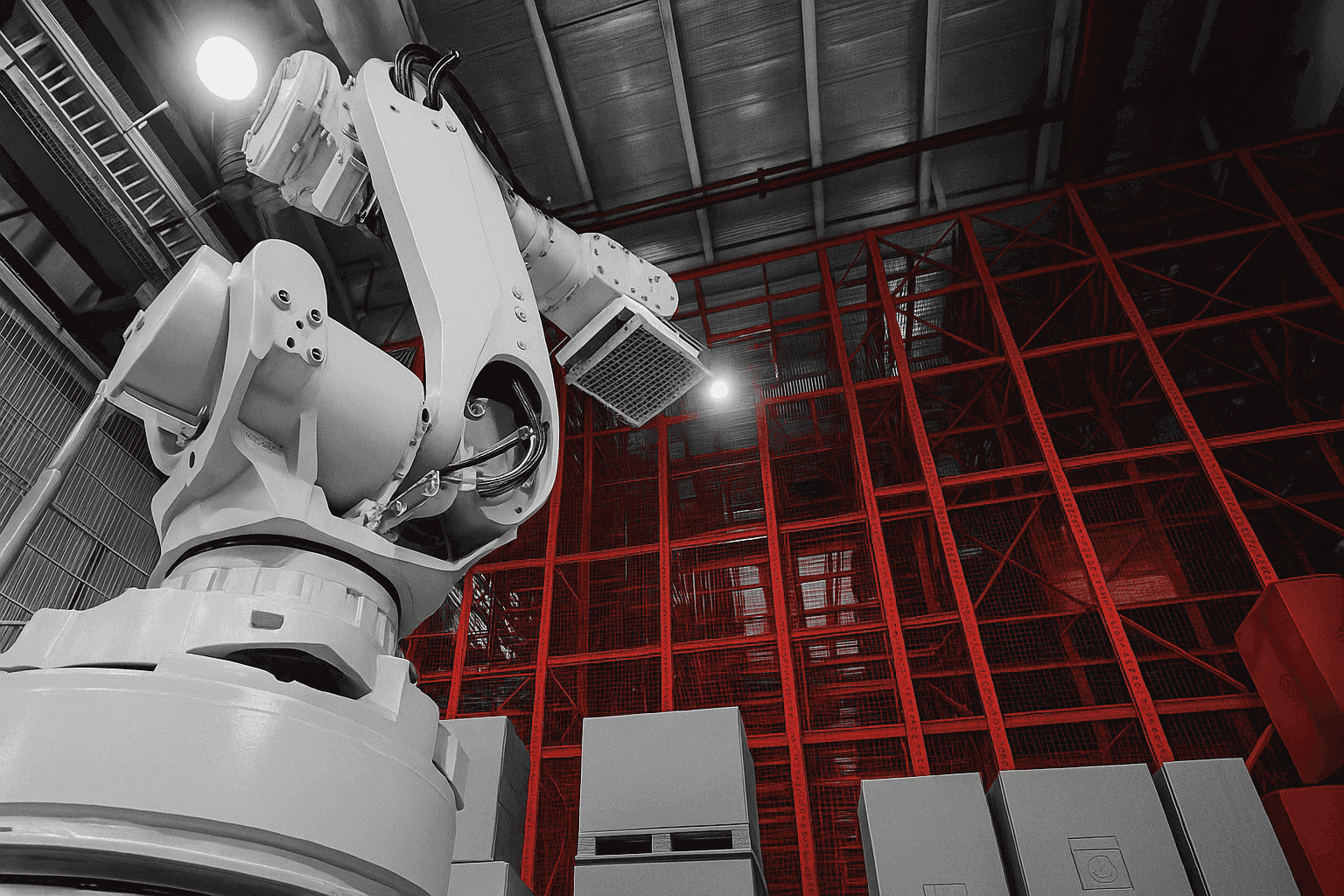

Contemporary conveyor systems go far beyond simple belt systems. Roller conveyors, sortation systems, and vertical lifts create three-dimensional pathways that efficiently navigate complex facility layouts. Advanced sortation technology can redirect items to hundreds of different destinations based on order requirements, shipping methods, or downstream capacity.

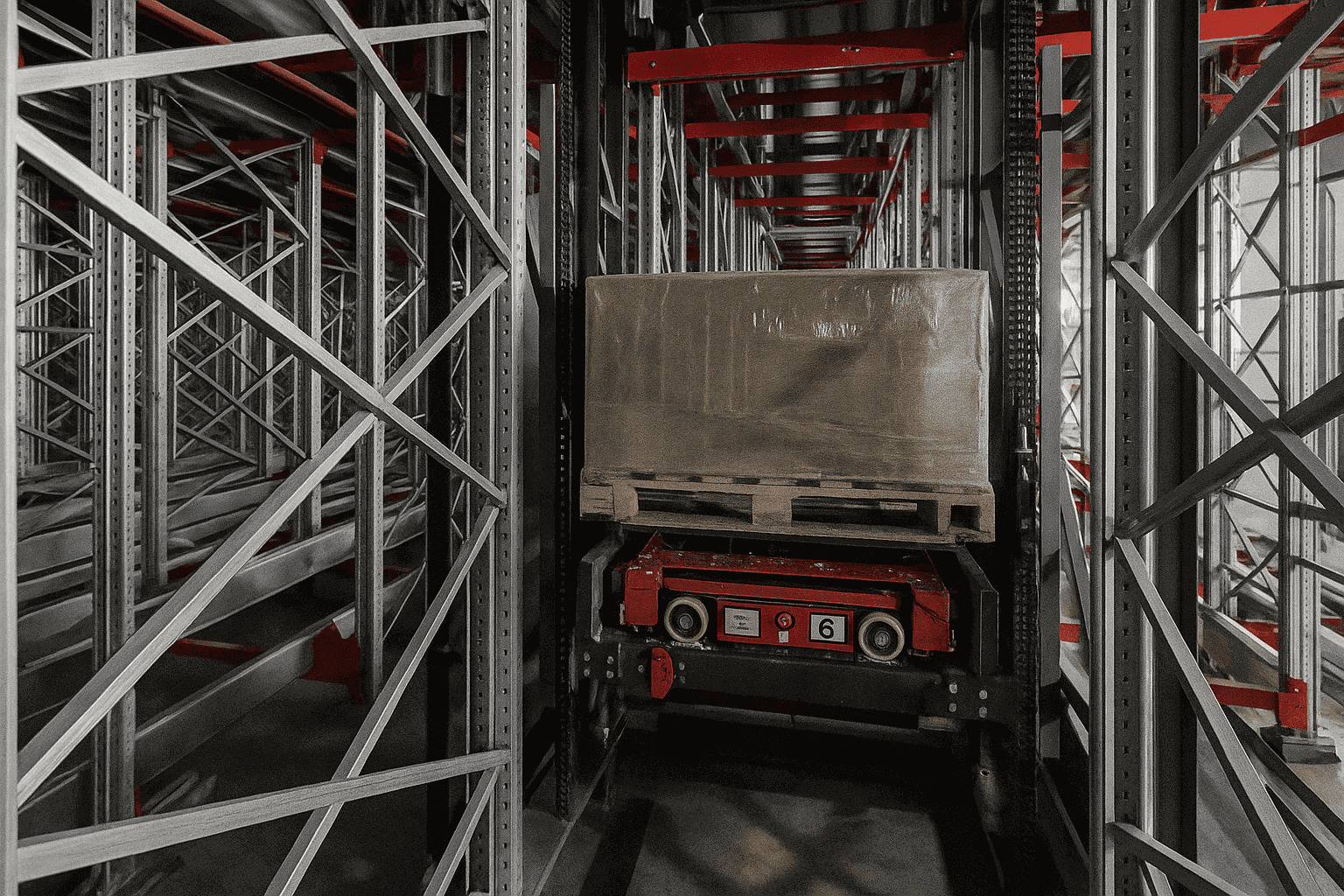

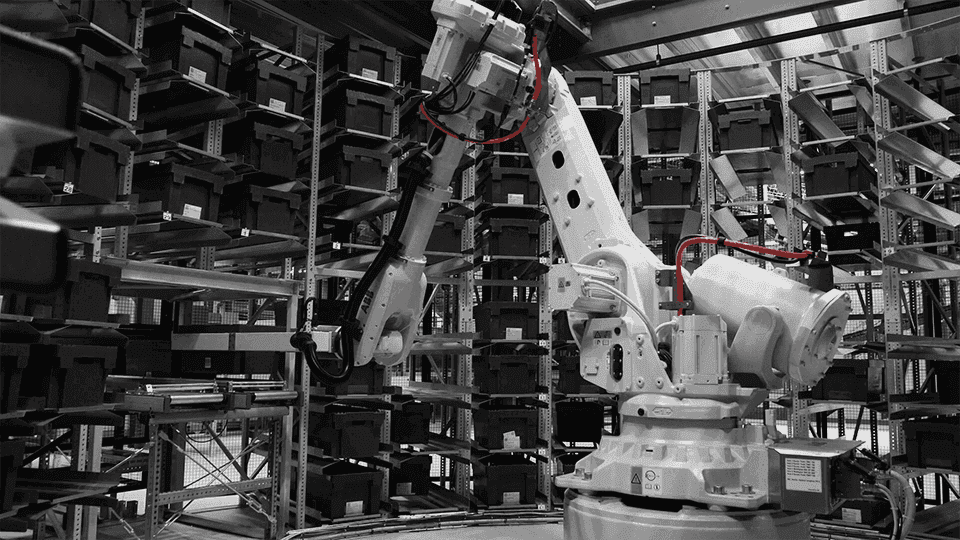

The integration between conveyors and AS/RS creates particularly powerful synergies. When an AS/RS crane retrieves an item, it places the container onto a conveyor that automatically routes it to the appropriate picking station. After order completion, conveyors transport finished orders to packing areas and eventually to the correct shipping door.

This continuous flow eliminates the start-stop inefficiency of batch processing. Rather than waiting for a picker to complete an entire pick list before moving to the next task, automated systems keep materials constantly moving towards their destination.