Optimising Throughput and Accuracy

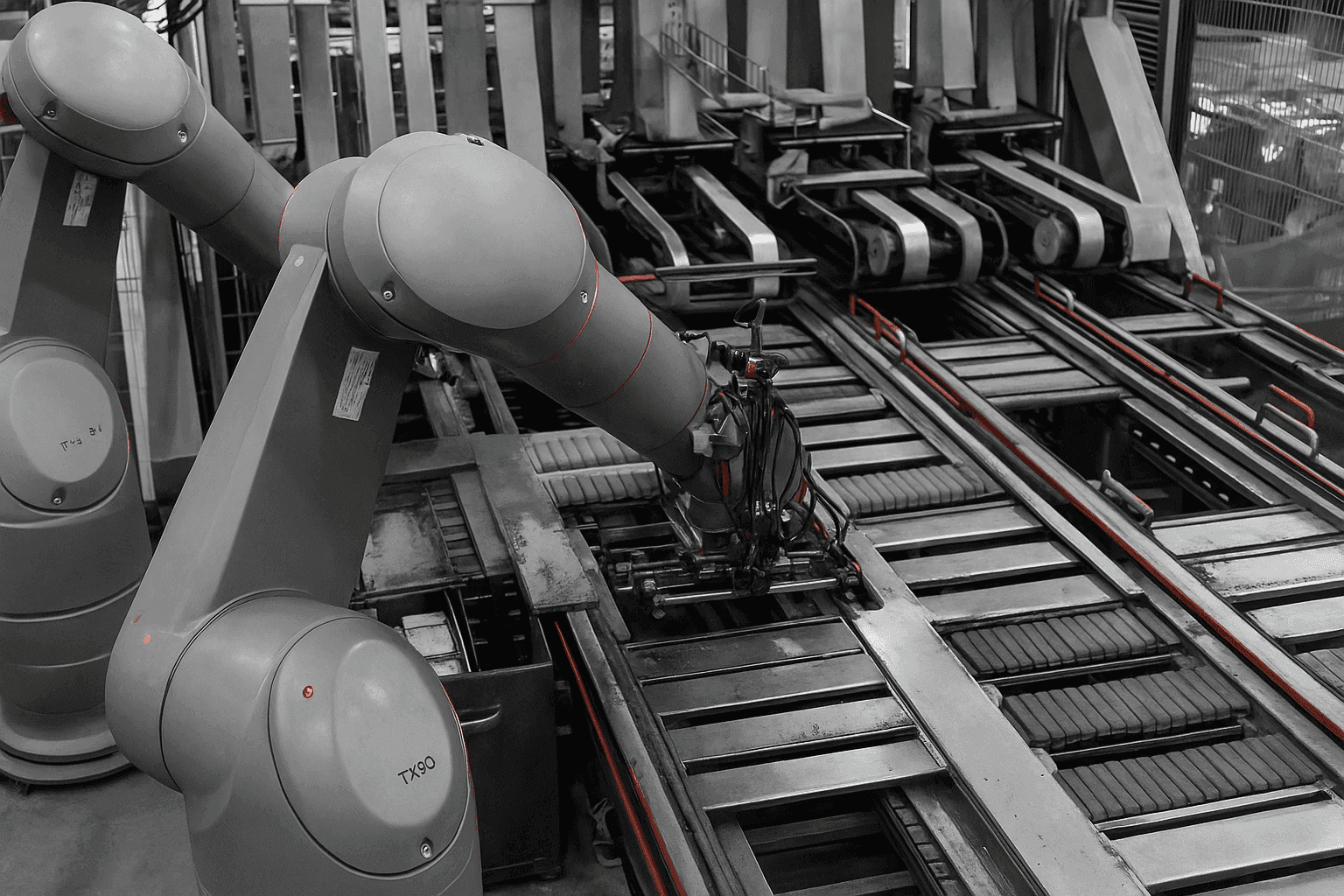

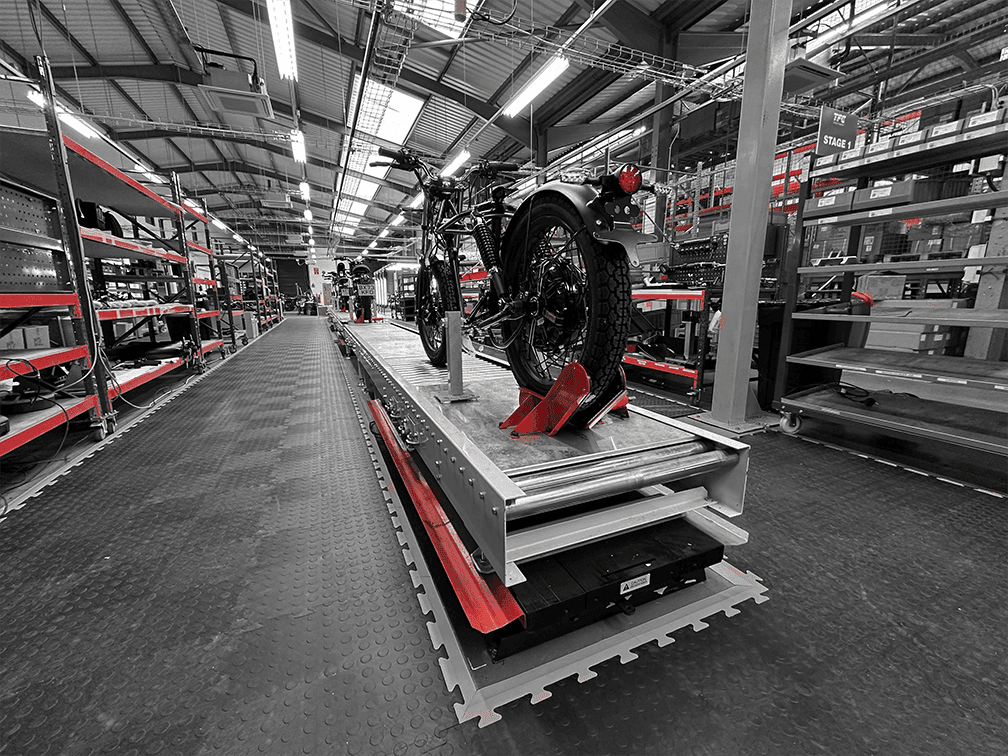

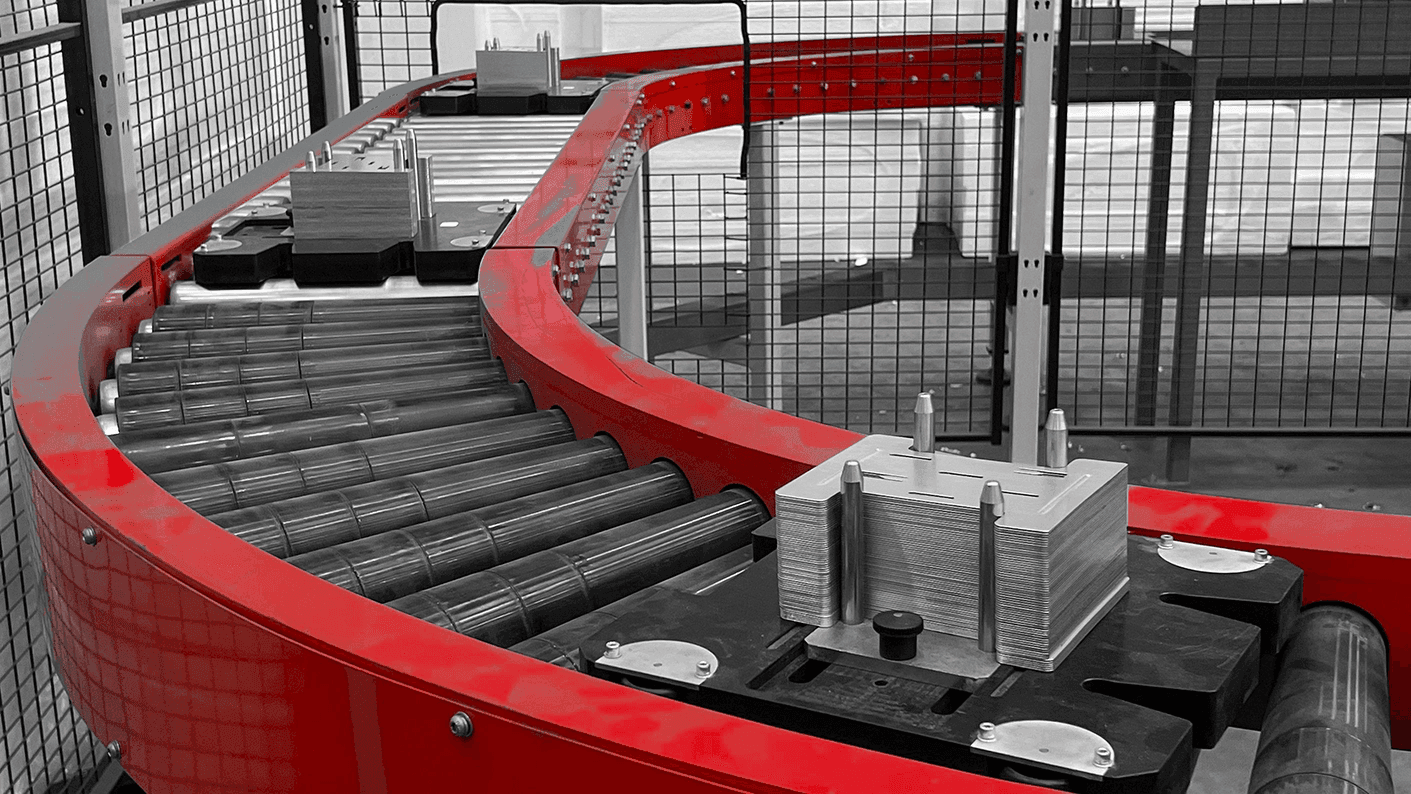

Automated material handling processes products with a level of consistency that manual operations cannot match. Robotic handlers maintain precise positioning, ensuring items arrive at their destinations in optimal condition. Error rates in picking and sorting diminish significantly, reducing the costly issue of mis-shipped orders and avoidable returns. When combined with a warehouse management system, robotic handlers create intelligent workflows that adapt in real time. As demand patterns shift or unexpected delays arise, automated systems reroute products dynamically, maintaining flow efficiency without the need for manual intervention or rapid replanning.

The performance benefits extend even further. Automated systems provide real-time inventory management and full traceability, ensuring stock movements remain accurate throughout fast-moving operations. Accuracy improvements reduce the likelihood of errors and mis-shipments, while enhanced responsiveness helps businesses maintain high service levels during peak trading periods. Streamlined coordination across multiple automation solutions ensures smoother product flow, and improved uptime is achieved through continuous load testing and proactive maintenance planning. This combination of accuracy, visibility, and resilience becomes particularly valuable during peak seasons, when traditional operations often struggle to maintain service consistency.

Scalability and Future-Proofing Operations

One of the most compelling advantages of automated material handling systems is their scalability. Unlike manual processes that require proportional increases in workforce to cope with rising demand, robotic infrastructure expands modularly. Businesses can add capacity incrementally, aligning investment with operational needs without the complexities associated with large-scale recruitment or rapid training. This creates a more predictable and sustainable growth model for warehouses and production environments.

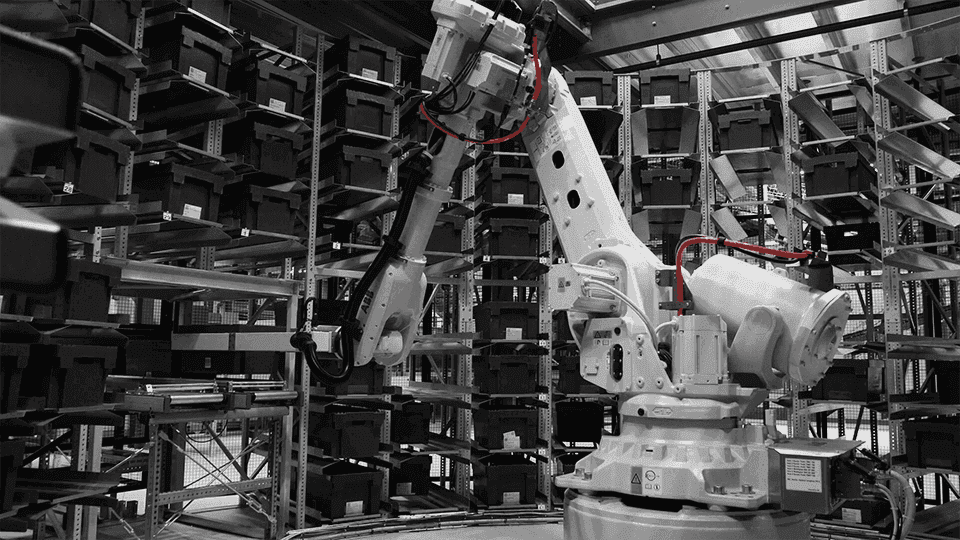

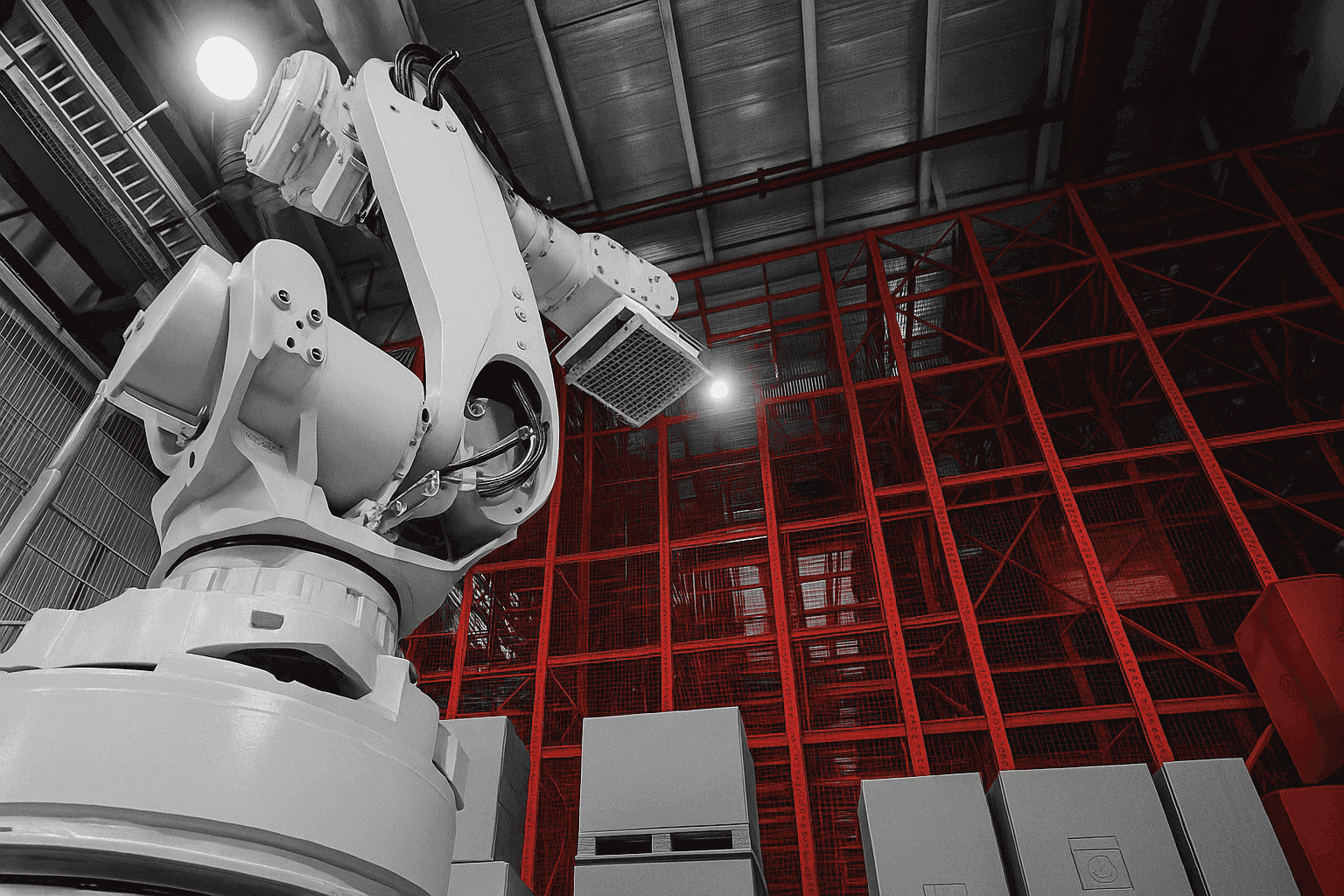

Automation also brings a level of flexibility that protects long-term investment. Modern systems are designed to be reconfigured as product ranges evolve or as facility layouts change. This adaptability ensures the automation remains relevant, even as business models shift or consumer behaviours fluctuate. Scalable solutions commonly include automated packaging technologies, goods-to-person systems that lift pick rates, dense storage systems such as ASRS units, and mechanical handling systems tailored to specific product mixes. Robotics can also be integrated with existing industrial automation infrastructures, enabling businesses to modernise gradually without large-scale disruption.

These advancements help optimise production flow while ensuring operations remain resilient in the face of shifting customer expectations, seasonal fluctuations, and wider global supply chain challenges.