Key Industries Benefiting from High-Speed Conveyors

Food and beverage production represents one of the largest adopters of high-speed conveyor technology. Bottling lines, packaging operations, and processing facilities routinely handle thousands of units per hour. A modern beverage bottling plant, for example, may process upwards of 50,000 bottles hourly, requiring sorting belt conveyors and pallet conveyors capable of maintaining consistent flow rates whilst coordinating with filling, capping, and labelling equipment.

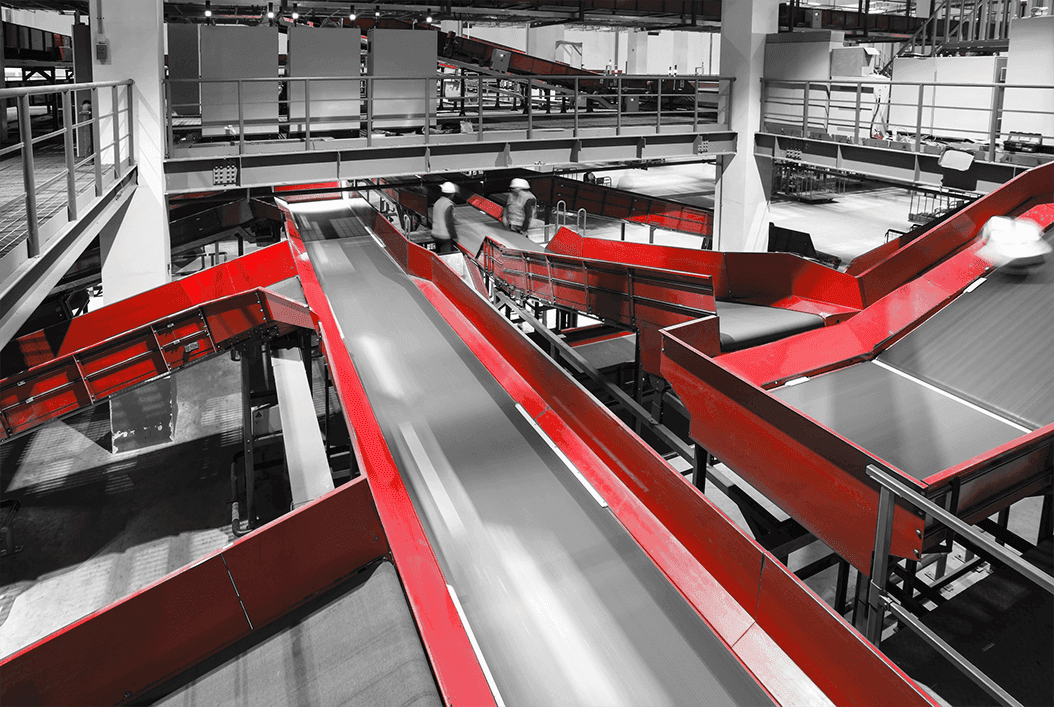

E-commerce fulfilment centres have similarly embraced conveyor automation systems to meet escalating delivery expectations. With consumers increasingly demanding next-day or same-day delivery, distribution facilities must sort and route thousands of parcels per hour. Automated sortation conveyors equipped with scanning and diverting mechanisms enable this level of throughput while improving warehouse logistics and customer satisfaction.